ICCP(Impressed Current Cathodic Protection)

HOW DOES AN ICCP SYSTEM WORK?

|

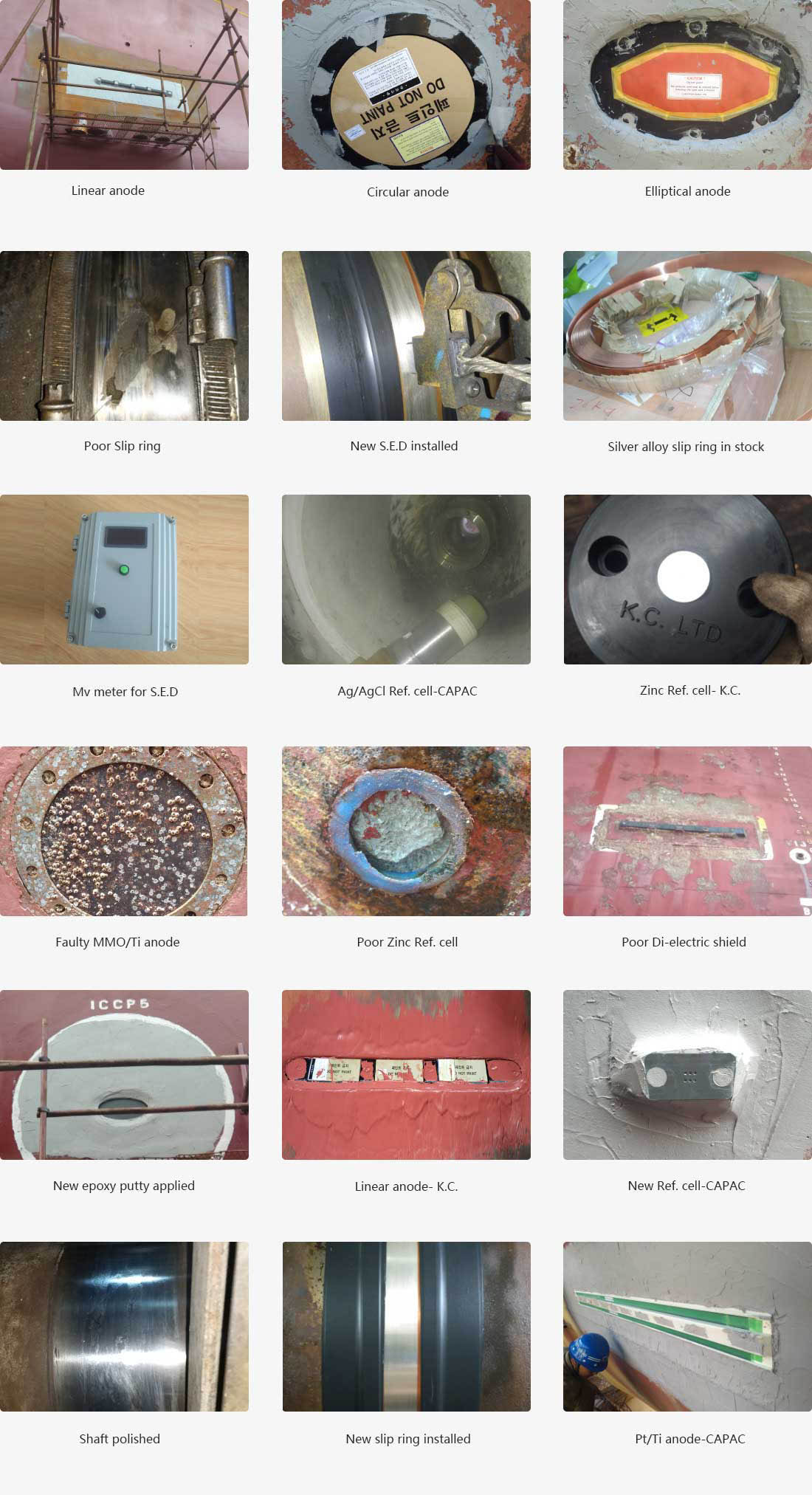

Although modern hull coatings provide some protection against corrosion they do not offer a complete solution. For this reason, most operators choose to protect their vessels with a purpose designed impressed current cathodic protection system. Using an arrangement of hull mounted anodes and reference cells connected to a control panel(s), the system produces a more powerful external current to suppress the natural electro-chemical activity on the wetted surface of the hull. |

This eliminates the formation of aggressive corrosion cells on the surface of plates and avoids the problems which can exist where dissimilar metals are introduced through welding or brought into proximity by other components such as propellers.

The systems are designed to automate the current output while the voltage output is varied. This allows the protection level to be maintained as the seawater resistivity alters. In a sacrificial anode system, increases in the seawater resistivity can cause a decrease in the anode output and a decrease in the amount of protection provided. With ICCP systems protection does not decrease in the range of standard seawater.

An essential feature of ICCP systems is that they constantly monitor the electrical potential at the seawater/hull interface and carefully adjust the output to the anodes in relation to this. Therefore, the system is much more effective and reliable than sacrificial anode systems where the level of protection is unknown and uncontrollable.

By installing a C-Shield system, operators can make significant savings in hull maintenance costs as well as achieving reductions in fuel costs by having a smooth hull surface. Furthermore, the system will safeguard the owner's investment and ensure greater safety through stronger hull integrity.

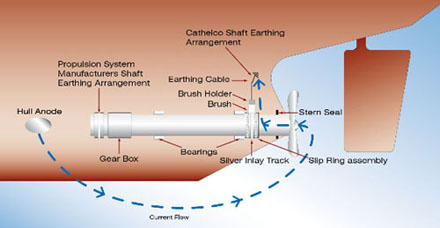

SHAFT EARTHING ASSEMBLY:

Even on ships fitted with ICCP or sacrificial anode systems, propeller shaft bearings are vulnerable to corrosion. This is because turning shafts are electrically insulated from the hull by the lubricating oil film in the bearings and by the use of non-metallic bearings in the tail shaft. The problem can be eliminated if the shaft is earthed to the hull using a propeller shaft slipring. Cathelco supply complete shaft earthing assemblies consisting of a pair of high silver content/graphite brushes mounted in a balanced brush holder, running on a copper slipring with a solid silver inlay track. This combination has been proved to give the optimum electrical continuity.

PORTABLE CORROSION MONITORING KIT

How can you be sure that your vessel's cathodic protection system is working properly?Whether you have a sacrificial anode or an impressed current system it is important to know whether it is functioning effectively to prevent hull corrosion. The Portable Corrosion Monitoring System is an essential piece of equipment for ship's crew. It provides a means of testing the electrical activity in seawater surrounding the hull (which causes corrosion) and a way of measuring it against a recommended standard. Inadvertent connections to an un-isolated shore grounding can be easily detected, enabling action to be taken to avoid galvanic corrosion.

Readings can be made when a vessel returns to moorings to ensure that there is no drain on the Cathodic protection system from other vessels or via jetties and piers as the resulting of a grounding fault from the AC shore supply.